Mail room warehouse trolley with fold down sides. 250kg capacity. 985mm(L) x 680mm(W) x 1,145mm(H)

⚠ Assembly required

Mail room warehouse trolley with fold down sides. 250kg capacity. 985mm(L) x 680mm(W) x 1,145mm(H) is backordered and will ship as soon as it is back in stock.

Description

Description

This cage trolley with 2-stage fold-down sides is a versatile and robust solution designed for a range of uses, including mailrooms. parcel transportation, clean and soiled linen handling, rubbish collection, mobile storage, and general-purpose applications. With a 250kg load capacity, it is the ideal choice for industries such as commercial laundries, warehousing, and industrial operations.

Built tough to withstand heavy-duty use, this mesh trolley is designed for reliability and durability in demanding environments. Its unique two-stage folding doors provide easy, unobstructed access to the trolley’s contents, making loading and unloading quick and hassle-free.

Supplied flat-packed for economical shipping, this cage trolley ensures cost-effective delivery while minimising storage space when not in use. Its fold-down sides further enhance flexibility, allowing for compact storage when empty and efficient transport of various items when in use. Fits through standard doorways - perfect for confined work environments.

- Unique two-stage folding doors for easy and unobstructed access

- 680mm(W) x 985mm(D) x 1,145mm(H).

- 250kg load capacity

- 4x swivel castors with brakes

- 125mm rubber wheels for quiet operation

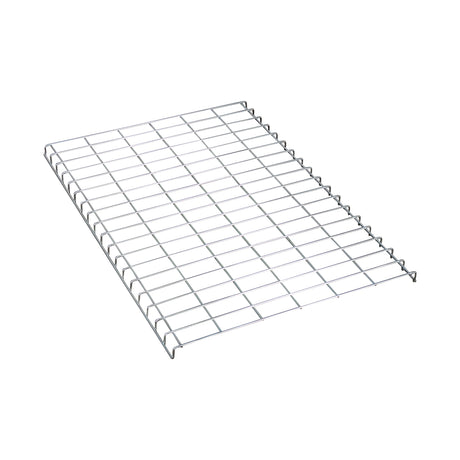

- Heavy-duty mesh construction for durability

- Fold-down sides for enhanced functionality and compact storage

- Supplied flat-packed for economical shipping

Can be fitted with a drop-in base shelf for extra storage.

Whether you’re managing clean or soiled linen in a commercial laundry, transporting parcels in a warehouse, or collecting rubbish in an industrial setting, this cage trolley delivers unmatched versatility and efficiency.

Note: Some assembly is required.

Specifications

Specifications

-

Outer dimensions

-

Fits through standard doorways

-

Unit weight

-

Load capacity

-

Castors & wheels

-

Frame material

-

Finish

Care & Maintenance

Care & Maintenance

Inspecting and Maintaining Your Equipment:

The safe use of roll cages, trolleys, and rolling equipment by team members relies on the optimal condition of the equipment. Hence, it is imperative to consistently carry out inspections and maintenance to uphold both employee safety and the longevity of the equipment.

Ensuring the safety of your staff and averting major issues can be achieved by adhering to a regular maintenance schedule and conducting routine checks - we recommend these checks to be undertaken every 3 months at a minimum.

- Visual Inspections – Regularly inspect all equipment for indications of wear and tear, such as bent frames, damaged wheels, or loose bolts and fasteners.

- Functional Testing – Confirm the functionality of the equipment, ensuring that brakes, wheels, and other components are operating correctly.

- Repairs and Replacements – Swiftly address identified issues by promptly repairing or replacing damaged roll cages, trolleys or components with genuine ANTECK parts to sustain safe operations.

- Cleaning – Consistently clean equipment to eliminate grease, dirt, or debris, preventing any interference with performance and alleviating potential safety hazards. Do not clean with harsh chemicals or abrasive wipes.

Shipping Information

Shipping Information

- This product is delivered via parcel courier.

- Redeliveries may incur additional costs.

- Want to use your own carrier? No problem! Just select 'pick up' at the checkout and we will let you know when your order is ready to collect.

Estimated transit times - by parcel courier

Estimated transit times - by tail-lift truck

2-stage fold down sides

Ergonomically designed

Super manoeuvrable