Z base roll cage. 4 sided with base and mid shelves. Full height and split doors

Our range of Z base style roll cages are built tough and are perfect for commercial laundries, linen, supermarkets, retail, warehousing, distribution, spare parts, 3PL, hospitality, bulk mobile storage and more. The applications are limitless!

These roll cages have been designed specifically for Australian conditions! With safety and quality in mind, they feature user hand protection, braked castors and easy-to-see bright coloured handles, so they won't get lost in your warehouse!

- 500kg total load capacity.

- Z style base frame.

- Nestable with other Z frame roll cages.

- 4-sided with base and mid shelves. 1* full height door and 1* split door.

- Zinc plated finish.

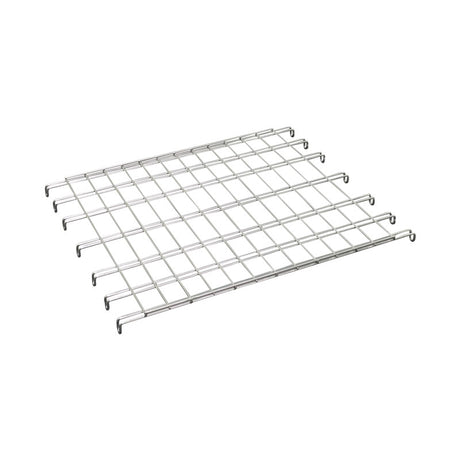

- Foldable mid-shelf fitted.

- 2x rigid castors and 2x swivel brake castors for superior manoeuvrability.

- Fits through standard doorways.

- Recessed handle designed to protect operator's hands from impacts.

- Supplied fully assembled - ready to use!

Can be fitted with a range of accessories, including:

- Water resistant cover.

- Washable liner.

- Recycling pouch.

- Drop-in shelf.

-

Outer dimensions

-

Internal dimensions

-

Nesting

-

Unit weight

-

Load capacity

-

Base frame style

-

Castors & wheels

-

Door configuration

-

Base shelf installed

-

Mid shelf installed

-

Frame material

-

Finish

-

Download info sheet

Accessories for this roll cage

Bundle deals for this roll cage

Important Shipping Information

Important Shipping Information

- This product is delivered via tail-lift truck.

- Redeliveries may incur additional costs.

- Want to use your own carrier? No problem! Just select 'pick up' at the checkout and we will let you know when your order is ready to collect.

Care & Maintenance

Care & Maintenance

Inspecting and Maintaining Your Roll Cage:

The safe use of roll cages by team members relies on the optimal condition of the equipment. Hence, it is imperative to consistently carry out inspections and maintenance to uphold both employee safety and the longevity of the equipment.

Ensuring the safety of your staff and averting major issues can be achieved by adhering to a regular maintenance schedule and conducting routine checks - we recommend these checks to be undertaken every 3 months at a minimum.

- Visual Inspections – Regularly inspect all roll cages and equipment for indications of wear and tear, such as bent frames, damaged wheels, or loose bolts and fasteners.

- Functional Testing – Confirm the functionality of the roll cage, ensuring that brakes, wheels, and other components are operating correctly.

- Repairs and Replacements – Swiftly address identified issues by promptly repairing or replacing damaged roll cages or components with genuine ANTECK parts to sustain safe operations.

- Cleaning – Consistently clean carts to eliminate grease, dirt, or debris, preventing any interference with performance and alleviating potential safety hazards. Do not clean with harsh chemicals or abrasive wipes.